By 2006, programs running on desktop PCs had attained the same capability. Within 40 years, in 1997, chess engines running on super-computers or specialized hardware were capable of defeating even the best human players. The early programs played so poorly that even a beginner could defeat them.

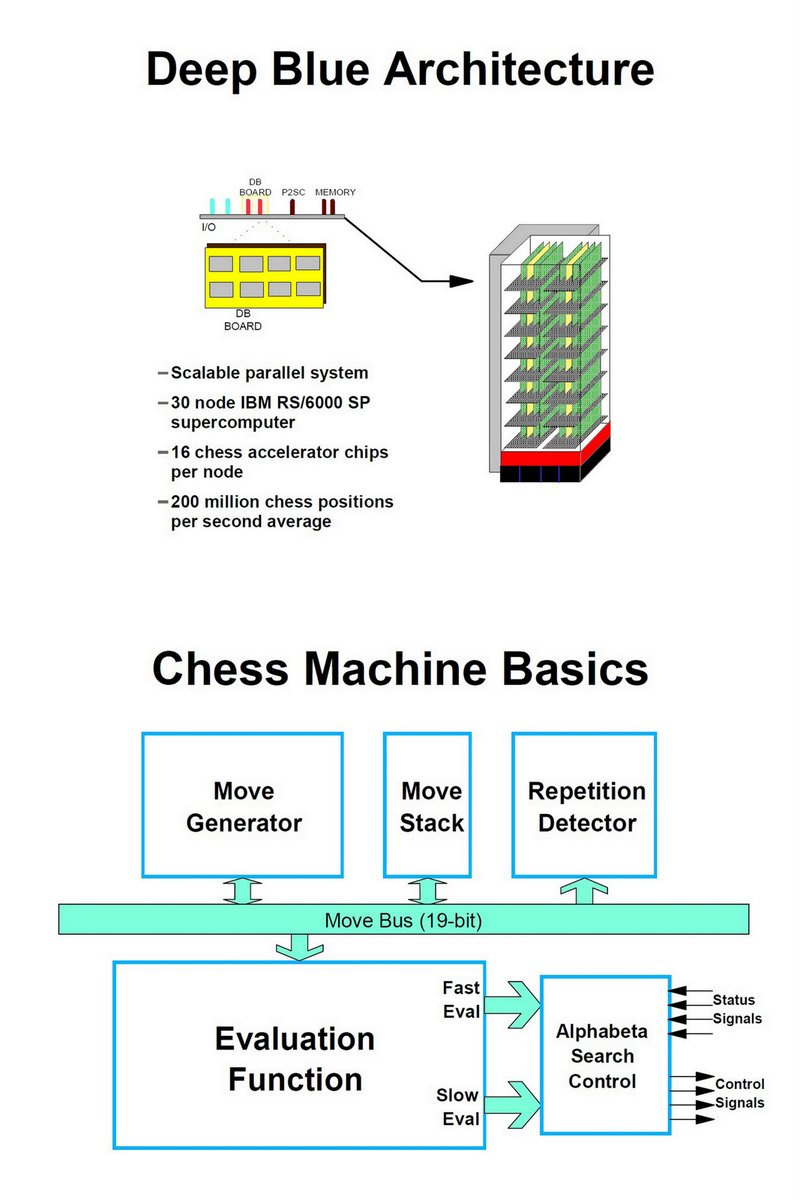

The first chess machines capable of playing chess or reduced chess-like games were software programs running on digital computers early in the vacuum tube computer age (1950s). The computational speed of modern computers, capable of processing tens of thousands to hundreds of thousands of nodes or more per second, along with extension and reduction heuristics that narrow the tree to mostly relevant nodes, make such an approach effective. Such trees are typically quite large, thousands to millions of nodes. Stockfish, GNU Chess, Fruit, and other free open source applications are available for various platforms.Ĭomputer chess applications, whether implemented in hardware or software, utilize different strategies than humans to choose their moves: they use heuristic methods to build, search and evaluate trees representing sequences of moves from the current position and attempt to execute the best such sequence during play.

Standalone chess-playing machines are also available. Computer chess provides opportunities for players to practice even in the absence of human opponents, and also provides opportunities for analysis, entertainment and training.Ĭomputer chess applications that play at the level of a chess master or higher are available on hardware from supercomputers to smart phones. Furthermore, AI-based manufacturing application, their implementation, and current development in intelligent manufacturing have also been discussed.Computer chess includes both hardware (dedicated computers) and software capable of playing chess. This review paper discusses various AI implementation-based intelligent manufacturing industries with their architecture and technology systems based on the integration of AI with manufacturing and information communication. It can be possible by combining traditional manufacturing and machining technologies with recently developed intelligent manufacturing technologies comprising hardware and software techniques. With the advancement in manufacturing technology, there is a need to execute these technologies and AI more efficiently and cost-effectively. this has triggered a valuable transformation in means, models, and ecosystems within the manufacturing industry and AI development.

For the past few years, the rapid progress and development of artificial intelligence (AI) based technologies have been analyzed for the applications of the intelligent manufacturing industry, i.e., industry 4.0.

0 kommentar(er)

0 kommentar(er)